- Topics

- Automotive industry

- Standardization and technical standards

- Electrical/electronic components and general system requirements

Norms and standards

Norms develop in line with vehicles

Various aspects, such as new technologies or changing customer demands, require norms to be continuously updated.

Various aspects, such as new technologies or changing customer demands, require norms to be continuously updated.

- Topics

- Automotive industry

- Standardization and technical standards

- Electrical/electronic components and general system requirements

Electrical/electronic components and general system requirements

The work group (NA052-00-32AA) is concerned with the following standardization topics:

- E/e components and parts (e.g., starter motors, generators, ignition systems, car radios, alarm systems, fuses)

- Electromagnetic compatibility

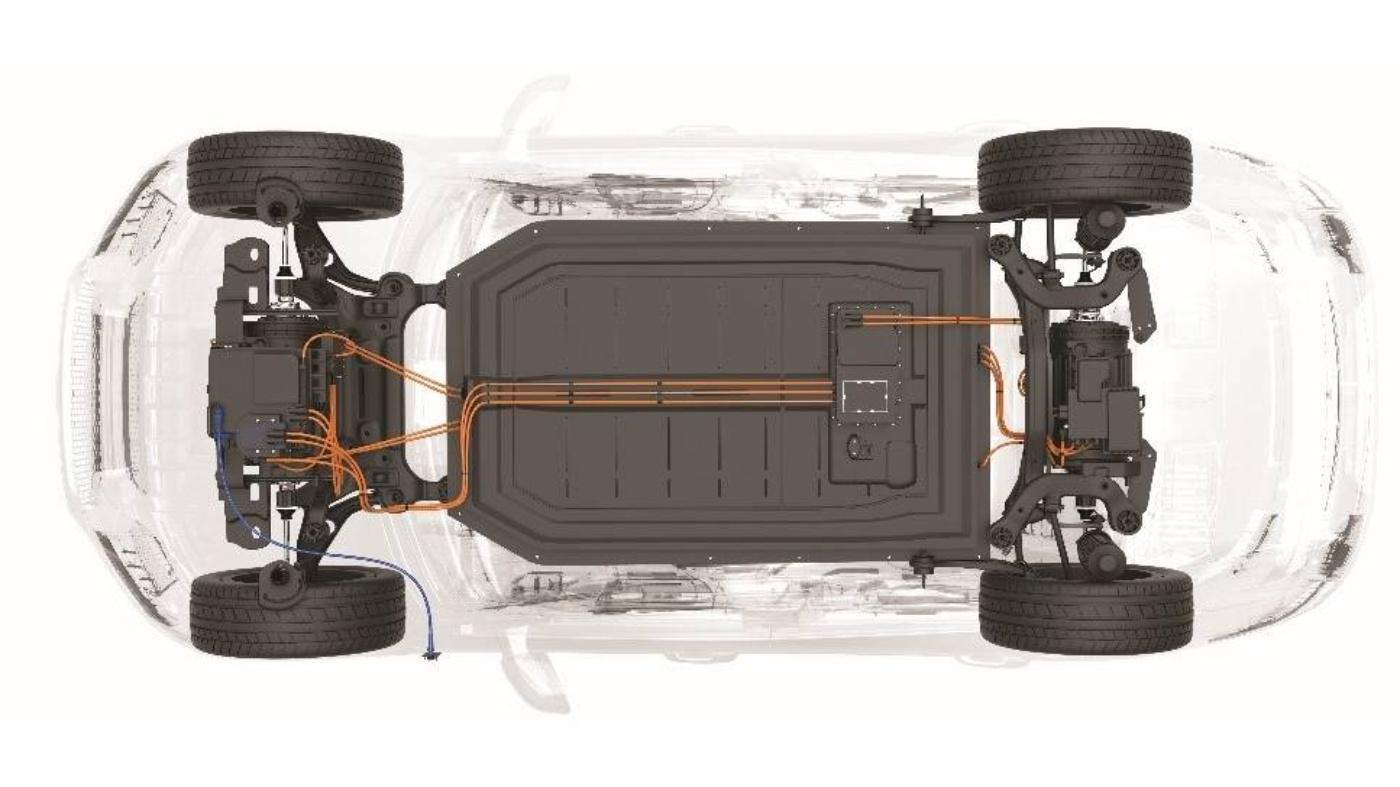

- Wiring systems and their components (plugs, connectors, fuses)

- Special plugs (e.g., plugs for trailers, diagnostics)

- Terminal labeling

- Environmental operations conditions for e/e components

- Functional safety and that of the intended function

- Automotive security engineering

- Software update engineering

- Automated driving.

The requirements for e/e components with regard to safety, reliability, environmental protection, and comfort are constantly being adapted and discussed in the working groups of the AA32 working committee at national and international level. The results are implemented in the standardization documents. In particular, the increasing networking of systems in the vehicle, the introduction of new technologies, the greater demands for comfort, and the adaptation to the legal framework of exhaust and safety regulations require constant further development/updating of the content.

Depending on the stage of development for the respective components/systems, different activities result in the working groups.

The following key topics are being worked on in AA32:

- Specifying the requirements for e/e components and their testing with regard to external influences during use in motor vehicles (e.g., vibrations, temperatures, chemicals). The ISO 16750 series of standards (Road vehicles – Environmental conditions and tests for electrical and electronic equipment) is continuously updated based on the latest developments and findings.

- Safety is one of the central issues when developing road vehicles. The development and integration of new features reinforces the need for functional safety and proof that functional safety goals are met. With the trend toward increasing technological complexity, software content, and mechatronic implementation, there is a greater risk of systematic as well as accidental hardware failures that must be considered in the context of functional safety. The ISO 26262 series of standards (Road vehicles – Functional safety) provides guidance on mitigating these risks by providing appropriate requirements and processes. A future challenge will be the inclusion of automated driving.

- The increasing digitization of transport and the subsequent networking require suitable measures to safeguard security-critical electronic systems against unauthorized external access to the vehicle over its entire life cycle. Legislation sets the conditions for this; norms and standards support manufacturers/suppliers in their implementation.

Current examples in this field are ISO/SAE 21434 (Road vehicles – Cybersecurity engineering), ISO PAS 5112 (Guidelines for testing cybersecurity engineering), and ISO 24089 (Software update engineering).

- The scope of AA32 also includes partial aspects pertinent to automated driving. The aim of these activities is to draw up an overview and manual of the steps to developing and validating a vehicle equipped with a safe automated driving system. The approach taken is based on high-level safety objectives and basic principles derived from globally applicable publications. It considers safety by design, as well as verification and validation methods for automated driving, with a focus on SAE Level 3 and Level 4 vehicles according to ISO/SAE PAS 22736, and taking cybersecurity into account at all the stages described.

- Automation of wiring harness manufacture

The aim of these activities is the future automation of the wiring harness by defining specifications for its development, manufacture, and structure. Based on these specifications, requirements for the digital data and the formats used to describe the product are derived. Pre-defined parameters should enable the assessment and comparison of the efficiency and effort required to achieve a desired degree of automation. In addition, recommendations are given for quality inspection adapted to automated manufacturing.